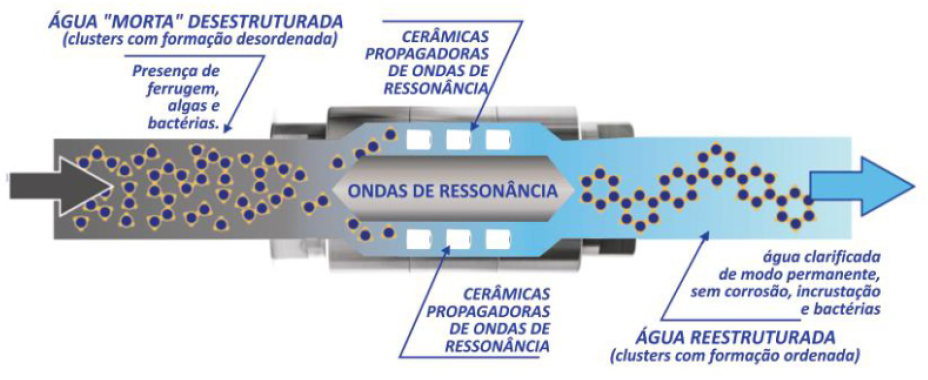

ECOLOGICAL WATER TREATMENT:

CLOSED CIRCUITS WITHOUT CHEMICALS. ANTICORROSIVE / ANTI-SCALING / BIOLOGICAL CONTROL

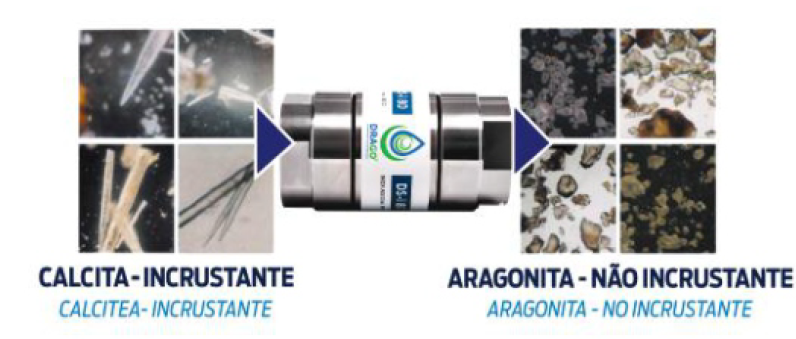

The permanent contact of water with several resonance-generating minerals contained inside the equipment, will be able to change the crystalline shape of calcium and magnesium carbonates in a non-fouling orthorhombic condition, in addition to meeting all the mineral needs that water needs to maintain itself. structured. As the new format of calcium and magnesium carbonate is abrasive, the old calcifications will be gradually removed, due to the friction of the water flow.

The bacteria will be eliminated from the circuit for lack of food (corrosion).

The results using DS-I:

✔ Elimination and prevention of corrosion;

✔ End of new incrustations and cleaning of existing calcifications;

✔ Permanent bacteriological control;

✔ Reduction of purges;

✔ Improved thermal exchange performance;

✔ TOTAL elimination of chemicals, biocides and corrosion inhibitors;

✔ Energy saving;

✔ Reduced maintenance and labor costs.